WELCOME TO DAHKEN

Take superior quality and cordial service to satisfy customer requirements.

Take superior quality and cordial service to satisfy customer requirements.

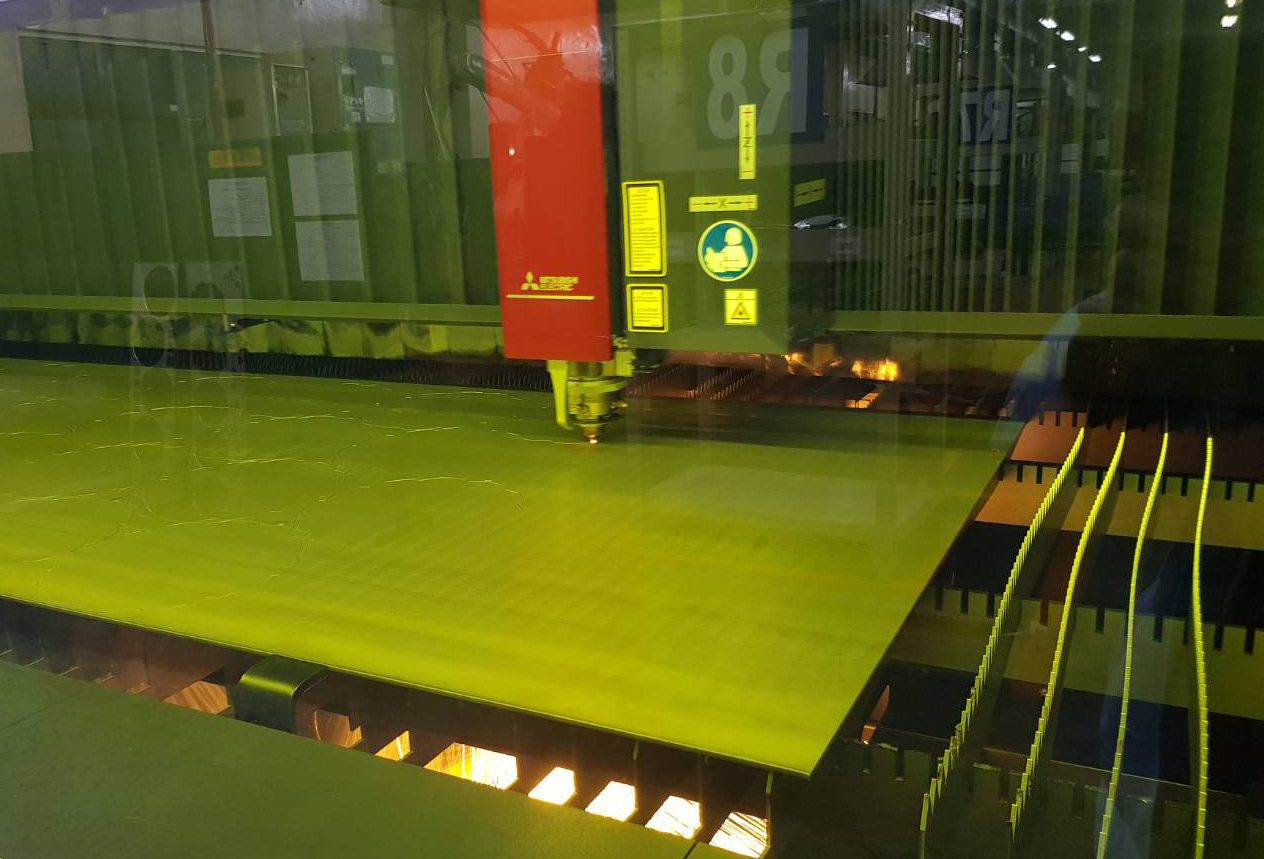

Laser machining machine with Mitsubishi fiber laser technology is able to cut steel, stainless steel, aluminum alloy, brase etc. and suitable for thin sheet metal working piece with small quantity and without mold.

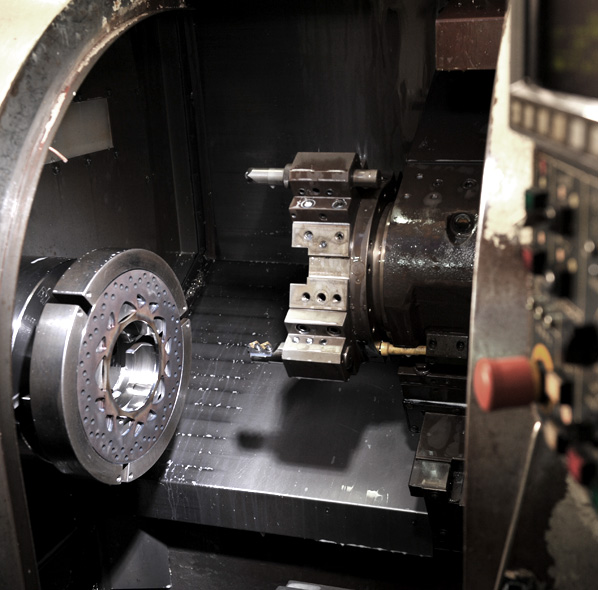

The lathe is a machine tool mainly to perform lathe turning on a rotating workpiece. Also, the drill bit, expanding auger, reamer, screw tap, tap and knurling tool, etc. can be used for lathe to make corresponding processing. Lathe is mainly used to machine with rotating surface; and it is the machine tool that is most widely used in the machinery manufacturing and repair & assembly factories.

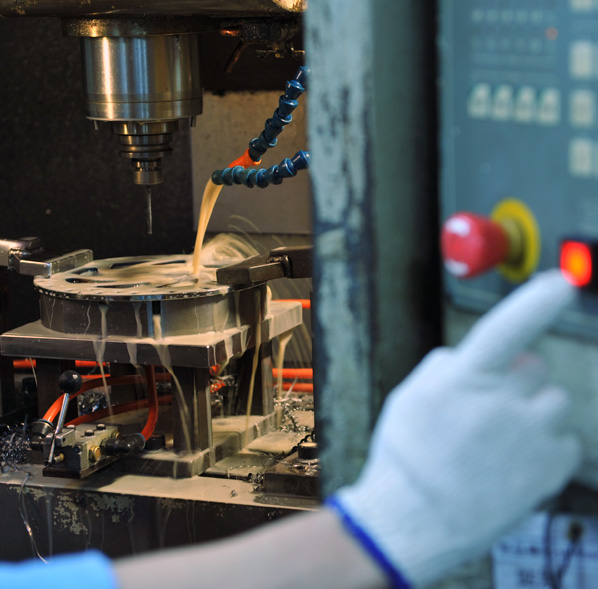

Principal items of processing technology by MC milling machine include: curve surface milling, groove milling and cam milling, etc.; also, a forming milling cutter can be used to mill a complex contour for just once.

The lapping machine is a grinder that uses a lapping tool with abrasive material inlaid to polish the surface of workpiece. It is mainly used to polish the high-precision plane of workpiece.

The high-frequency heat treatment machine applies an electromagnetic induction method to the material for processing; a quick heating and cooling method to enhance the material hardness.

Ultrasonic cleaner uses a conductive function of high-speed agitation to drive the medium in liquid that generates countless minute vacuum bubbles to result in a cavitations effect. These countless tiny vacuum bubbles will be fractured when pressed by agitation to produce strong impact force that can displace the dirt from the surface and crevice & blind side of object for cleaning to obtain a thorough cleaning effect!

Double-surface lapping machine can lap both sides of a plane workpiece to accomplish the requirements of high-efficiency lapping and high-precision double-side lapping for precision workpiece.

To inspect the important safety items of brake disc: plate thickness, vibration amplitude, deflection, radial direction, and circumference direction.

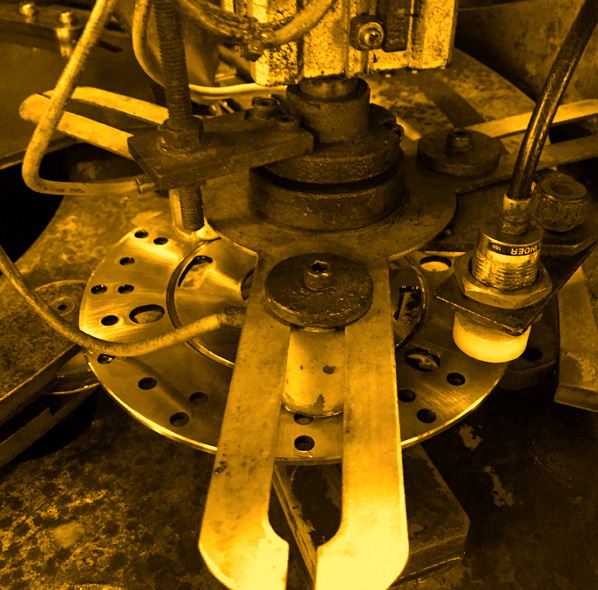

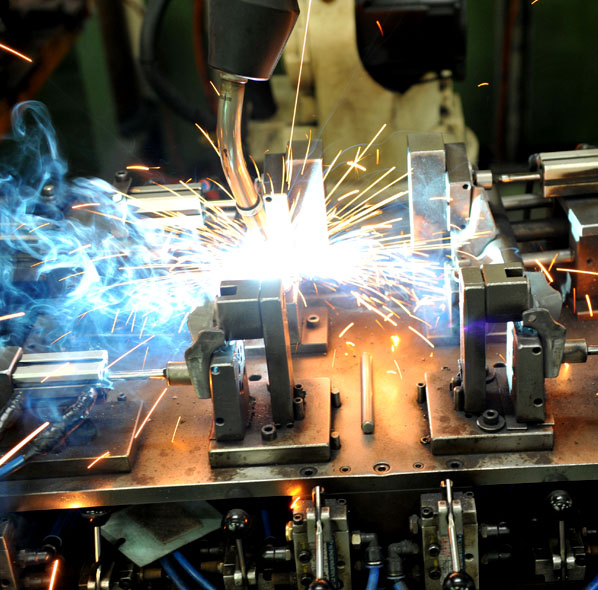

Advantages of automatic welding: (1) Stable welding quality and enhanced welding homogeneity; (2) Effectively improved production efficiency and uninterrupted work; (3) Improved workers' working environment to a large extent for them to work in a safe working environment; (4) Reduced requirement of manual operation technique for workers; (5) Realized batch production; (6) Able to realize the high-precision and stable quality welding, increase welding quality and production efficiency.

Functions of punching machine include: To punch & shear, form, deep-draw and forge metal; generally it will be worked with the molds and it is the important equipment for producing metallic machine parts.

1. A honing mandrel is used to hone the workpiece via its gyration and up/down reciprocating motion.

2. The honing mandrel is comprised of 1 or more than 1 rod-like rubstones.

3. The rubstone and workpiece will be contacted in a rectangular cross-section to perform the gyration, reciprocating and pressing motion for precision processing.

4. The finished surface will have an excellent sliding surface.

1. When processing is in operation, workpiece is immobilized while broaching tool is performing the linear cutting motion.

2. Suitable for processing the through hole, plane and forming surface.

3. Advantages:①High productivity ② High processing precision and small surface roughness ③ Simple broaching machine structure and operation

1. Workpiece is supported by a support plate and a guide roller while grinding wheel is used for lapping.

2. It is constituted by three mechanisms: grinding wheel, adjustment wheel and workpiece supporting plate.

3. Grinding wheel performs the grinding work while adjustment wheel controls the rotation of workpiece to in-feed workpiece for lapping.

4. It is mainly to lap cylindrical workpiece.